-

برونو ناسيمنتوأشكركم على مساعدتكم الدائمة ودعمكم في توفير منتجات عالية الجودة وبأسعار معقولة

برونو ناسيمنتوأشكركم على مساعدتكم الدائمة ودعمكم في توفير منتجات عالية الجودة وبأسعار معقولة -

(إحسان سلماري)الإجابة السريعة والموقف المهني يجعل تعاوننا أكثر سلاسة!

(إحسان سلماري)الإجابة السريعة والموقف المهني يجعل تعاوننا أكثر سلاسة!

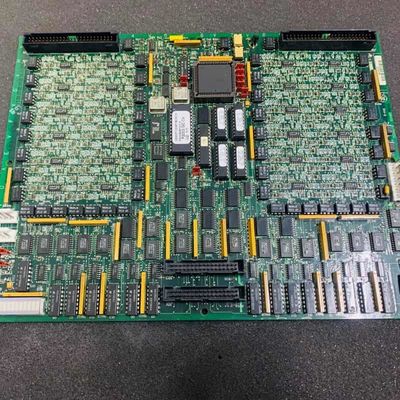

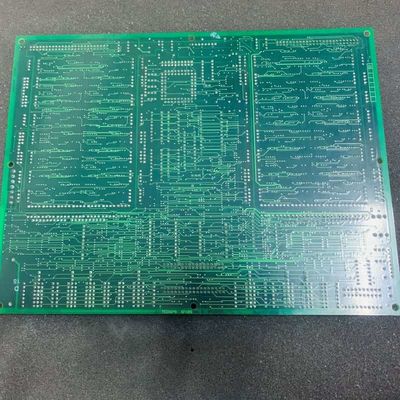

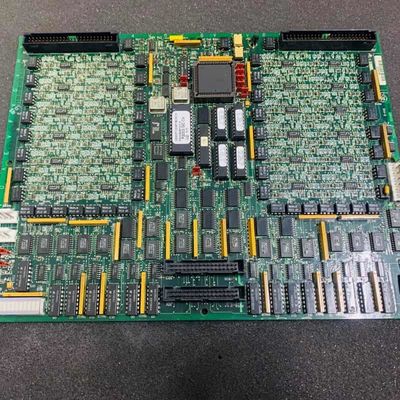

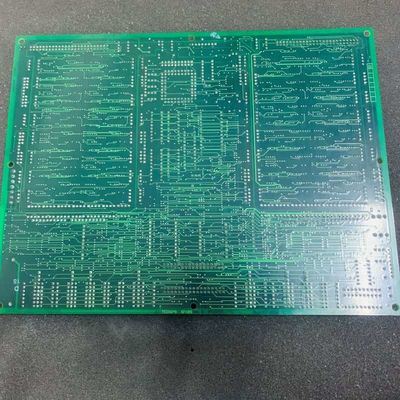

لوحة الإدخال/الإخراج الرقمية GE DS200TCDAG1B بارتفاع 200 مم وعرض 100 مم ووزن 2 كجم للتحكم في توربينات Mark V

| اسم | GE DS200TCDAG1B DS200TCDAG1BCB الإدخال/بطاقة الإخراج الرقمية علامة التوربين | معرف المنتج | DS200TCDAG1B |

|---|---|---|---|

| مسلسل | مارك الخامس | وظيفة | حزمة الإخراج المنفصلة |

| منتج صافي/طول | 330mm | ارتفاع صافي المنتج | 200 مم |

| عرض صافي المنتج | 100 مم | الوزن الصافي للمنتج | 2 كجم |

| ضمان | 1 سنوات | ||

| إبراز | لوحة إدخال/إخراج رقمية بارتفاع 200 مم,لوحة إدخال/إخراج رقمية بعرض 100 مم,لوحة إدخال/إخراج رقمية بوزن 2 كجم,100mm Width Digital I/O Board,2kg Weight Digital I/O Board |

||

GE DS200TCDAG1B DS200TCDAG1BCB بطاقة إدخال/إخراج رقمية Mark V للتحكم في التوربينات

تفاصيل المنتج:

GE DS200TCDAG1B هي لوحة إدخال/إخراج رقمية مصممة حصريًا لنظام التحكم في التوربينات Mark V من GE’s—وهي سلسلة قديمة تستخدم لإدارة محركات التوربينات الهوائية والغازية والبخارية الآلية، وواحدة من خطوط GE Mark النهائية التي تدمج تقنية التحكم Speedtronic الحاصلة على براءة اختراع.

من الناحية الوظيفية، تعالج إشارات تناظرية متنوعة: مدخلات/مخرجات 4-20 مللي أمبير عبر JBB/JAA، مع انخفاض التيار عبر مقاومات العبء لقراءة الجهد، ومدخلات RTD عبر JCC/JDD، وتوفير الإثارة وقياس المقاومة المعتمدة على درجة الحرارة، ومدخلات المزدوجة الحرارية عبر JAR/S/T، باستخدام تعويض الوصلة الباردة لـ TBQA’s لحساب درجة الحرارة الفعلية، وإشارات جهد/تيار عمود التوربين عبر JBB. يتم إرسال جميع الإشارات المهيأة إلى محرك الإدخال/الإخراج عبر موصل 3PL، مع تكوين البرنامج لأنواع المزدوجات الحرارية، وإعدادات RTD التي تتم إدارتها من خلال محرر تكوين الإدخال/الإخراج الخاص بـ HMI.

الميزات الرئيسية:

التعامل الشامل مع الإشارات التناظرية:يعمل كمحور مركزي لإشارات 4-20 مللي أمبير، وRTDs، والمزدوجات الحرارية، وجهد/تيار العمود—وتوسيع نطاق البيانات وتهيئتها ونقلها إلى محرك الإدخال/الإخراج، وهو أمر بالغ الأهمية لمراقبة أداء التوربينات والتحكم فيها. إنه يعمل على تحسين الإشارات الأولية للقضاء على الضوضاء، مما يضمن بيانات دقيقة توجه التعديلات في الوقت الفعلي مثل تدفق الوقود أو تعديلات نظام التبريد.

وحدات PROM القابلة للإزالة والحساسة لـ ESD:تقوم وحدات PROM القابلة للإزالة بتخزين البرامج الثابتة؛ يؤدي استبدالها بحماية ESD مثل أشرطة المعصم إلى التأكد من أن لوحات الاستبدال تتطابق مع وظائف الأصل من خلال الاحتفاظ بتعليمات متطابقة. هذا يتجنب إعادة تكوين البرامج الثابتة، وتقليل وقت الصيانة وضمان منطق معالجة الإشارات المتسق بعد الاستبدال.

الأجهزة والبرامج القابلة للتكوين:تتعامل ثلاثة وصلات (J1/JP2/JP3) مع تعديلات الأجهزة، بينما تقوم إعدادات البرنامج بتخصيص أنواع المزدوجات الحرارية/RTD ومعلمات الإشارة—والتكيف مع احتياجات التوربينات المتنوعة. يدير J1 منافذ RS232، ويساعد JP2 في الاختبار، ويتكيف البرنامج ليتوافق بسلاسة مع إعدادات المستشعر الخاصة بالتوربين.

واجهة المكونات المخصصة:تسعة موصلات (ثمانية وظيفية، وواحد أثري) تربط بلوحات Mark V الرئيسية (TCPS، CTBA، TBCA، TBQA) لنقل الطاقة والبيانات وإشارات التشخيص بسلاسة، مما يلغي مخاطر التداخل. يضمن الدور المحدد لكل موصل وصول الإشارات إلى الأهداف دون تدخل، مما يعزز استقرار النظام.

تصميم يركز على الاختبار:تدعم الوصلات (JP2/JP3) والموصلات المتخصصة اختبار المصنع والصيانة، مما يبسط استكشاف الأخطاء وإصلاحها مع ضمان موثوقية التشغيل المعياري. يقوم JP2 بتعطيل المذبذبات للاختبار الآمن، وتتيح الموصلات للفنيين الوصول إلى الإشارات بسهولة لتشخيص المشكلات بسرعة.

![]()

![]()

| DS200DTBBG1ABB | DS200TCCAF1BDF |

| DS200SDCIG2AFB | IS200ISBBG1AAB |

| DS200SDCIG2AHB | IS200CABPG1BAA |

| DS200BDAAG1AAA | IS200DSFCG1AEB |

| DS200SIOBH1ABA | IS200DRLYH1BBB |