-

برونو ناسيمنتوأشكركم على مساعدتكم الدائمة ودعمكم في توفير منتجات عالية الجودة وبأسعار معقولة

برونو ناسيمنتوأشكركم على مساعدتكم الدائمة ودعمكم في توفير منتجات عالية الجودة وبأسعار معقولة -

(إحسان سلماري)الإجابة السريعة والموقف المهني يجعل تعاوننا أكثر سلاسة!

(إحسان سلماري)الإجابة السريعة والموقف المهني يجعل تعاوننا أكثر سلاسة!

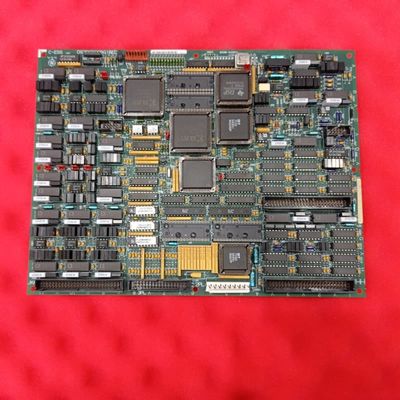

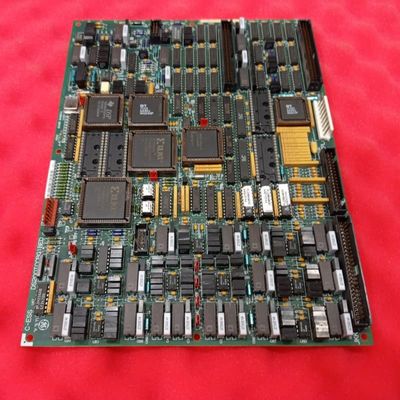

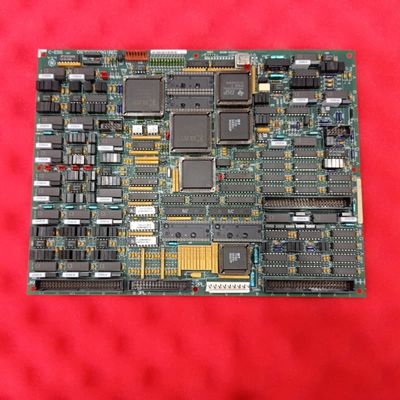

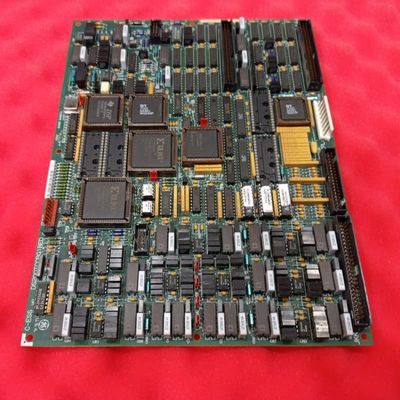

GE DS200TCCAG1B TC2000 Common Analog Board with 80196 Microprocessor 50-pin Connectors and Removable PROM Modules for Mark V Turbine Control

| اسم | GE DS200TCCAG1B DS200TCCAG1BAA I/O TC2000 لوحة التناظرية MARK V GE TURPINE | معرف المنتج | DS200TCCAG1B |

|---|---|---|---|

| مسلسل | مارك الخامس | وظيفة | حزمة الإخراج المنفصلة |

| منتج صافي/طول | 330mm | ارتفاع صافي المنتج | 200 مم |

| عرض صافي المنتج | 100 مم | الوزن الصافي للمنتج | 2 كجم |

| ضمان | 1 سنوات | ||

| إبراز | 80196 Microprocessor Analog I/O Board,50-pin Connectors TC2000 Common Analog Board,Removable PROM Modules Mark V Turbine Control Board,50-pin Connectors TC2000 Common Analog Board,Removable PROM Modules Mark V Turbine Control Board |

||

GE DS200TCCAG1B DS200TCCAG1BAA I/O TC2000 Analog Board Mark V Ge Turbine Control

Product Details:

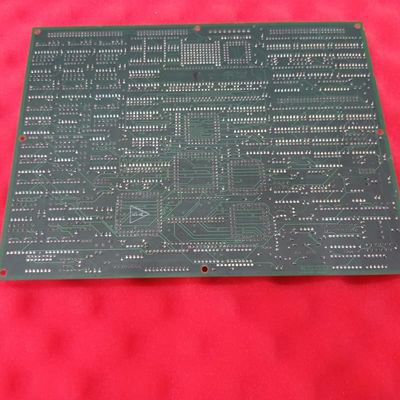

The GE DS200TCCAG1BAA is a TC2000 Common Analog I/O Board designed exclusively for GE’s Mark V Turbine Control System—a legacy series used to manage wind, gas, and steam turbine automated drives, and one of the final GE Mark lines to integrate the patented Speedtronic control technology. A revised variant of the original DS200TCCAG1 parent board, it serves as a core analog signal hub in Speedtronic Gas Turbine Control Systems, handling signal scaling, conditioning, and transmission between terminal boards and the system’s I/O Engine.

Hardware-wise, it features an 80196 microprocessor and removable PROM modules. It includes one side-visible LED, two 50-pin connectors, and nine specialized connectors for interfacing with Mark V components: 2PL (TCPS power), 3PL (data bus signals for STCA/TCCA/TCCB boards), JAA/JBB (CTBA terminal board 4-20 mA outputs/inputs), JCC/JDD (TBCA terminal board RTD inputs), JAR/S/T (TBQA terminal board inputs), JC (TCPS diagnostic signals), and a vestigial JEE connector (unused in normal operation). Three hardware jumpers (J1, JP2, JP3) enable configuration: J1 enables/disables the RS232 port, JP2 disables the oscillator for testing, and JP3 is for factory use.

Functionally, it processes diverse analog signals: 4-20 mA inputs/outputs via JBB/JAA, with current dropped across burden resistors for voltage reading, RTD inputs via JCC/JDD, supplying excitation and measuring temperature-dependent resistance, thermocouple inputs via JAR/S/T, using TBQA’s cold junction compensation to calculate actual temperature, and turbine shaft voltage/current signals via JBB. All conditioned signals are sent to the I/O Engine via the 3PL connector, with software configuration thermocouple types, RTD settings managed through the HMI’s I/O Configuration Editor.

Key Features:

Comprehensive Analog Signal Handling:Acts as a central hub for 4-20 mA signals, RTDs, thermocouples, and shaft voltage/current—scaling, conditioning, and transmitting data to the I/O Engine, critical for turbine performance monitoring and control. It refines raw signals to eliminate noise, ensuring precise data that guides real-time adjustments like fuel flow or cooling system tweaks.

Removable & ESD-Sensitive PROMs:Removable PROM modules store firmware; swapping them with ESD protection like wrist straps ensures replacement boards match the original’s functionality by retaining identical instructions. This avoids reconfiguring firmware, cutting maintenance time and ensuring consistent signal processing logic post-replacement.

Configurable Hardware & Software:Three jumpers (J1/JP2/JP3) handle hardware tweaks, while software settings customize thermocouple/RTD types and signal parameters—adapting to diverse turbine needs. J1 manages RS232 ports, JP2 aids testing, and software adjusts to match turbine-specific sensor setups seamlessly.

Dedicated Component Interfacing:Nine connectors (eight functional, one vestigial) link to key Mark V boards (TCPS, CTBA, TBCA, TBQA) for seamless power, data, and diagnostic signal transfer, eliminating cross-talk risks. Each connector’s specific role ensures signals reach targets without interference, boosting system stability.

Test-Focused Design:Jumpers (JP2/JP3) and specialized connectors support factory testing and maintenance, simplifying troubleshooting while ensuring normative operation reliability. JP2 disables oscillators for safe testing, and connectors let techs access signals easily to diagnose issues fast.

![]()

![]()

| DS200DTBBG1ABB | DS200TCCAF1BDF |

| DS200SDCIG2AFB | IS200ISBBG1AAB |

| DS200SDCIG2AHB | IS200CABPG1BAA |

| DS200BDAAG1AAA | IS200DSFCG1AEB |

| DS200SIOBH1ABA | IS200DRLYH1BBB |